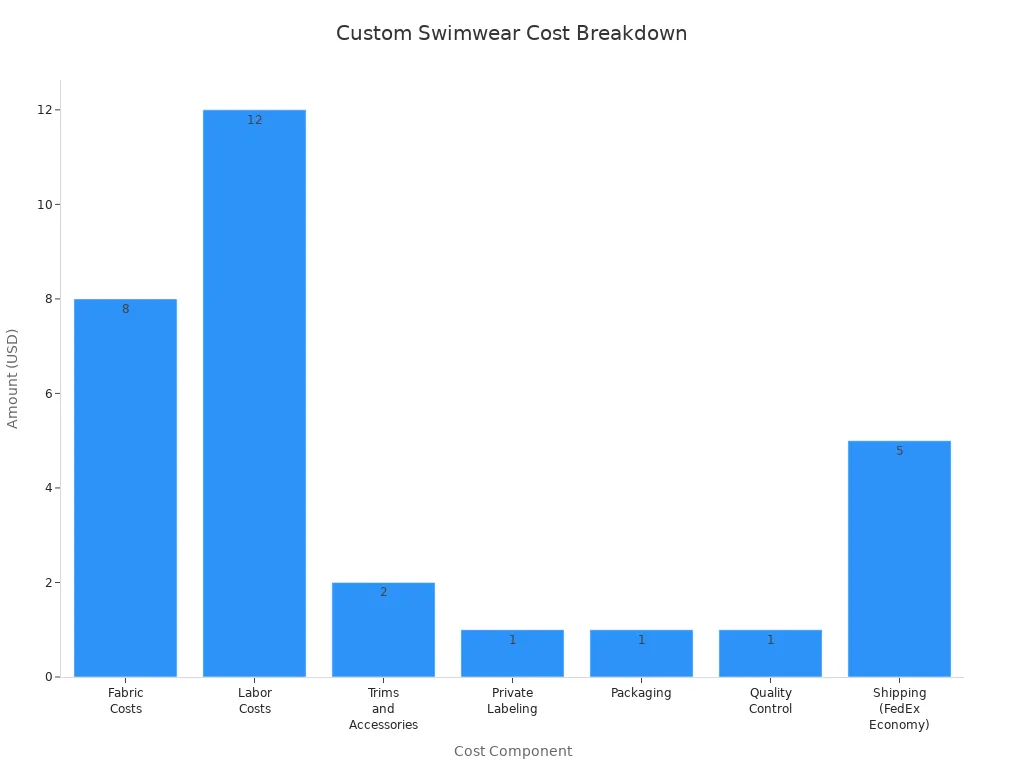

Si desea precios competitivos de un fabricante de trajes de baño personalizados, debe saber qué hace que los costos suban. Su presupuesto es importante en cada paso. Mire el material, la mano de obra y el envío cuando haga su presupuesto. Aquí hay un desglose para un conjunto de bikini:

Componente de costo | Importe (USD) |

|---|---|

Costos de la tela | $8 |

Costes laborales | $12 |

Adornos y accesorios | $2 |

Etiquetado privado | $1 |

Embalaje | $1 |

Control de calidad | $1 |

Envío (FedEx Economy) | $5 |

$30 |

Puede hacer que su presupuesto vaya más allá revisando las cotizaciones. Aprende dónde gastas más dinero. Su presupuesto lo ayuda a encontrar formas de ahorrar y obtener mejores ofertas.

Los puntos clave

Sepa cuánto cuesta hacer trajes de baño. Mira enCostos de materiales, Mano de obra y envío para ver dónde puede ahorrar dinero.

Escoja sus materiales cuidadosamente. Utilice telas de alta calidad y más baratas para mantener una buena calidad y ahorrar dinero.

Pregunte a varios fabricantes para las cotizaciones de precios. Esto le permite comparar precios y pedir mejores ofertas.

Ordene su traje de baño cuando no es la temporada alta. Comprar en este momento puede ayudarlo a obtener grandes descuentos.

HacerBuenas relaciones con sus fabricantes. Hablar bien con ellos puede ayudarle a obtener mejores precios y mejor calidad.

Conozca sus costos de producción de trajes de baño

SabiendoCostes de producción del traje de bañoTe ayuda a tomar buenas decisiones. Puede ahorrar dinero si sabe a dónde va su dinero. Esto le ayuda a encontrar maneras de gastar menos y obtener mejores ofertas. Veamos las principales cosas en las que debes pensar.

Materiales y Tejidos

Los materiales cuestan mucho en la producción de trajes de baño. Los precios cambian según el tipo y la calidad de la tela. Mejores telas, como las ecológicas, cuestan más. Son cómodos y duran más. Si quieres un mercado determinado, estas telas pueden valer la pena. El costo promedio de los materiales es$30.000 a $100.000Para una línea de trajes de baño. Para ahorrar, elija telas que sean más baratas pero que sigan siendo buenas. Pregunte a su fabricante acerca de descuentos por volumen u otras opciones para reducir los costos.

Consejo: Use telas premium y más baratas en sus diseños. Esto mantiene la calidad alta y los costos bajos.

Gastos laborales

La mano de obra es otra gran parte de los costos del traje de baño. Donde haces tu traje de baño importa mucho. Aquí hay un vistazo simple a los costos laborales en diferentes lugares:

País/Región | Ventajas | Consideraciones |

|---|---|---|

Vietnam | Menores costos laborales, buenos acuerdos comerciales | Infraestructura en crecimiento, algunos límites |

Tailandia | Los trabajadores cualificados, cerca de | Costos más que Vietnam, escala más pequeña |

Estados Unidos | Cerca del mercado, buen control de calidad | Altos costos laborales, no mucha capacidad |

Italia | Habilidad artesanal, nuevos diseños | Cuesta más, tarda más en hacer |

Marruecos | Cerca de Europa, buenos costos laborales | La industria textil está creciendo, problemas materiales |

Turquía | Buena calidad, producción rápida | Cuesta más que Asia, cambios en la cadena de suministro |

Portugal | Sostenible, de alta calidad | N/A |

Para mantener los costos bajos, elija países con mano de obra más barata. Compruebe siempre el tamaño mínimo de la orden. Algunos lugares dan mejores precios para pedidos más grandes.

Envío y embalaje

El envío y el embalaje también aumentan los costos. El envío rápido y el embalaje especial cuestan más. Para ahorrar, planifique con anticipación y evite las tarifas urgentes. Pregunte a su fabricante sobre el embalaje regular o los envíos grupales para pagar menos. El tamaño mínimo de la orden puede cambiar las tarifas de envío, así que ordene sabiamente.

Aquí hay algunos costos habituales por pieza:

La mayoría de los trajes de baño cuestan$9 a $30 +Para hacer.

Algunas líneas cuestan entre $5 y $20 cada una, dependiendo del diseño y los materiales.

Escoger telas más baratas y planificar pedidos le ayuda a controlar los costos. Esto mantiene su negocio de trajes de baño haciendo dinero.

Compare los fabricantes Traje de baño de encargo

Elegir el fabricante de trajes de baño personalizado adecuado es importante. Puede cambiar sus precios y lo buenos que son sus productos. Quieres buenos precios, pero también quieres que tu traje de baño sea de alta calidad. Aquí hay algunas cosas que debe verificar cuando mira a diferentes fabricantes.

Calidad y reputación

Mire la reputación y la calidad de cada fabricante. ElLos mejores fabricantes a menudo cuestan más. Usan mejores materiales y tienen reglas estrictas para hacer trajes de baño. Es posible que a las empresas más baratas no les importe tanto la calidad. Si un fabricante tiene una buena reputación, los clientes confiarán en su marca. Si desea que su marca de trajes de baño dure, elija un fabricante que se preocupe por la calidad.

Los principales fabricantes usan buenos materiales y tienen altos estándares.

Los fabricantes más baratos pueden bajar los precios pero también la calidad.

Una buena reputación le ayuda a mantener contentos a los clientes.

Solicitar cotizaciones

Siempre pida cotizaciones de algunos fabricantes. Esto le permite comparar precios y ver lo que paga. Proporcione todos los detalles sobre su línea de trajes de baño cuando solicite una cotización. Esto le ayuda a obtener el precio correcto y comparar costos.

Componente de costo | Descripción |

|---|---|

Gastos de material | |

Cargos laborales | Honorarios para los trabajadores que hacen su traje de baño. |

Tarifas de personalización | Costos adicionales por diseños o características especiales. |

Costos de envío | Gastos de envío, incluyendo embalaje y manipulación. |

Compruebe cuánto tiempo tarda en obtener sus productos. El tiempo puede cambiar con cada fabricante y diseño. Planifique sus acciones y anuncios en función de estos tiempos.

Verifique los costos de envío y cuánto tiempo tarda la entrega.

Piense en el transporte marítimo internacional y las aduanas.

Agregue impuestos y tarifas de importación a su presupuesto.

Acuerdos de Precios Transparentes

Las ofertas claras te ayudan a evitar problemas. Hable sobre precios, pagos y entregas con su fabricante. Escribe todo para que no haya confusión. Esto lo mantiene seguro y lo ayuda a controlar los costos.

Elemento clave | Descripción |

|---|---|

Precios | |

Documentación | Anote todas las ofertas para evitar confundidas más tarde. |

Asegúrese de incluir todos los detalles, como paquetes tecnológicos, opciones de telas, tablas de tallas, códigos de colores y pasos de empaque. Una buena comunicación le ayuda a obtener la calidad que desea y precios justos.

Consejo: Mira lo que es popular en el mercado. Las marcas directas al consumidor están reduciendo los precios, por lo que los precios son más competitivos. Si utiliza materiales sostenibles, suLos costes pueden subir un 20-30%. La tecnología AI ayuda a las marcas a cambiar los precios rápidamente, así que estate atento a los cambios cada temporada.

La comparación de los fabricantes de trajes de baño personalizados lo ayuda a encontrar la mejor combinación de precio y calidad. Puede ahorrar dinero y obtener mejores trajes de baño si hace su tarea y hace tratos claros.

Cantidades de pedido y presupuesto

Cantidades de orden mínimas (MOQs)

Cuando trabaje con fabricantes de trajes de baño, escuchará sobre moq. Esto significa cantidad mínima de orden. Cada fabricante tiene su propio moq. Cambia cuánto paga y cómo planea su presupuesto. Si desea comenzar una nueva línea de trajes de baño, debe conocer el moq para cada proveedor. Algunas empresas tienen unMoq bajo. Esto te ayuda a probar diseños sin gastar mucho. Otras compañías quieren que ordene más, lo que puede hacer que sus costos suban.

Aquí hay un vistazo rápido al moq estándar de los principales fabricantes:

Fabricante | Detalles de MOQ |

|---|---|

Fabricante de trajes de baño Miami | Bajos moqs para startups, ayudando a la primera producción. |

Buena empresa de ropa | Hace pequeños lotes para pruebas. |

Beerills | 45 piezas por estilo/color (stock), 90 (personalizado). |

La Isla | Normalmente 300 unidades por cada diseño. |

Si desea precios más flexibles, elija un fabricante con un moq más bajo. Esto le permite elegir cuánto pedir y evita que tenga demasiado stock adicional.

Descuentos a granel

Si ordena más trajes de baño, puede obtener mejores precios. Muchos fabricantes dan descuentos a granel para grandes pedidos. Ahorras dinero en cada traje de baño, por lo que obtienes más ganancias. Los pedidos a granel también lo ayudan a hablar con su proveedor sobre mejores precios. Las pequeñas empresas pueden usar estos descuentos para competir con marcas más grandes.

Comprar a granel le permite pedir precios más bajos por artículo.

Usted obtiene buenos descuentos cuando usted pide mucho a la vez.

La planificación de sus pedidos a granel le ayuda a no comprar demasiado y mantiene una buena calidad.

Los descuentos por volumen le ayudan a pagar menos por cada traje de baño y establecer mejores precios.

Si planifica bien el tamaño de su pedido, puede ahorrar dinero con estas ofertas.

Planificación de inventario

Una buena planificación de inventario le ayuda a evitar costos adicionales y trajes de baño desperdiciados. Debe adivinar cuántos venderá y ordenar la cantidad correcta. Esto mantiene su stock justo y le impide hacer demasiados. Utilice los datos de ventas y devoluciones de antes para ayudarle a decidir cuánto pedir. Las marcas a menudo ganan un 40% más de lo que necesitan, por lo que la planificación es muy importante.

Adivinar la demanda le ayuda a ver lo que quieren los clientes.

Utilice la suposición de la demanda y la gestión de inventario para mantener sus números correctos.

La producción justo a tiempo coincide con sus pedidos a la demanda real, por lo que desperdicia menos.

Revise su proceso con frecuencia para encontrar formas de ahorrar dinero y obtener mejores precios.

Mire las devoluciones para elegir los mejores tamaños y colores para su próximo pedido.

Si maneja bien el tamaño de su pedido, mantendrá los costos bajos y obtendrá los mejores precios de su fabricante.

Negociar precios

Para obtener el mejor precio de los fabricantes de trajes de baño, necesita un plan inteligente. Usted quiere gastar menos en la fabricación de trajes de baño y mantenerse por delante de los demás. Hay maneras de hablar con los fabricantes para obtener mejores precios y aún así mantener una buena calidad.

Condiciones de pago

Las condiciones de pago pueden cambiar la cantidad que usted paga. Algunos fabricantes quieren un depósito. Otros le permiten pagar más tarde. Si paga todo a la vez, puede obtener un descuento o pedir menos. Esperar más tiempo para recibir su pedido le ayuda a planificar y gastar menos. Siempre pregunte sobre las opciones de pago antes de aceptar.

Cada fabricante tiene diferentes formas de pagar, así que verifique primero.

El flujo de efectivo es importante. Los pedidos grandes pueden gastar su dinero, pero las buenas condiciones de pago ayudan.

Pagar temprano ayuda al proveedor a obtener dinero rápidamente. Esto puede significar mejores precios para usted.

Consejo: Pregunte si recibe una recompensa por volver a ordenar pronto. Puede obtener un precio más bajo o un trato especial.

Plazo flexible | Cómo ayuda a reducir MOQs |

|---|---|

Pago por adelantado | Ayuda al proveedor a obtener dinero más rápido |

Tiempo de plomo más largo | Facilita la planificación de la producción |

Precio unitario más alto | Cubre los costos de configuración y materiales |

Aprovechar cotizaciones múltiples

Siempre obtenga precios de más de un fabricante. La comparación de precios le ayuda a encontrar la mejor oferta. Si compartes tus planes y cuánto quieres pedir, los fabricantes saben que vas en serio. Esto puede ayudarle a trabajar juntos y controlar los costos.

Ser abierto sobre los costos genera confianza. Pida una lista de lo que cuesta cada parte antes de hablar sobre el precio.

Prepárese para alejarse si el precio no es bueno.

Si paga rápido o pide más, puede solicitar un descuento.

Táctica | Beneficio | Ejemplo del mundo real |

|---|---|---|

Fijar precios anuales | Previsibilidad presupuestaria | Tarifas de locked-in para temporada completa |

Precio efectivo más bajo | Descuento por pedidos de repetición rápida | |

Previsión de uso compartido | Planificación conjunta de ampliación | Bloquear el espacio de fábrica por adelantado |

Ciclos abiertos de retroalimentación | Relación/confianza | Fijaciones rápidas y descuentos en curso |

Nota: Un comprador de ropa deportiva necesitaba un envío rápido para un evento. Pagaron extra para obtenerlo rápidamente, pero consiguieron un precio más bajo por artículo para pedidos más grandes más tarde. Esto ayudó a ambas partes y ahorró dinero.

Construir relaciones con el fabricante

Tener una buena relación con su fabricante es muy importante. Si trata a su proveedor como un socio, puede ahorrar dinero y obtener mejores trajes de baño. Hablar a menudo y ser honesto conduce a más descuentos y mejores materiales.

Las relaciones a largo plazo te ayudan aBuenos materiales por menos dinero.

Trabajar juntos puede reducir los costos de envío y hacer las cosas más rápido.

Cuenta la historia de tu marca y visita la fábrica si puedes. Pagar siempre a tiempoY mantener su palabra.

Consejo: Las buenas asociaciones te ayudan a gastar menos y a vencer a otras marcas. Usted obtiene mejores precios y más ayuda para su negocio.

Reducir los costos de producción de trajes de baño

Simplicidad Diseño

Diseños simples le ayudan a gastar menos en la fabricación de trajes de baño. Si usa menos costuras y formas básicas, ahorra dinero. Los patrones fáciles significan menos trabajo para los trabajadores. Esto hace que la producción sea más rápida y más barata. Diseños limpios no necesitan tarifas adicionales para los detalles de lujo. Puede decirle a los clientes por qué su traje de baño cuesta menos, pero aún se ve bien. Los estilos simples le ayudan a mantener los precios claros.

Consejo: Pregunte a su fabricante por ideas para hacer diseños más simples. Esto puede reducir los costos, pero mantener su traje de baño elegante.

Materiales rentables

Elegir los materiales adecuados te ayuda a ahorrar dinero. Muchas marcas usan telas recicladas o ecológicas. Estas telas cuestan menos y atraen compradores. Mire cómo las diferentes marcas usan materiales inteligentes enLa mesa de abajo:

Marca | Materiales usados | Punto de precio |

|---|---|---|

Summersalt | TENCEL reciclado™, TENCEL Modal, Cupro | Relativamente barato |

Londré | Telas recicladas de botellas de agua | No especificado |

BOLD Nadar | Tejido biodegradable | No especificado |

Bravissimo | Tejido Ecowave de botellas y residuos | Alrededor de $100 |

Buceo nocturno | Materiales reciclados, incluidas las redes de pesca | No especificado |

Novia colectiva | ECONYL®(Nylon regenerado de viejas redes de pesca) | No especificado |

YouSwim | Un tamaño se adapta a la mayoría, materiales reciclados | $139 |

REI | Variedad de trajes de baño sostenibles | No especificado |

Nomads Bañadores | Varios trajes en diferentes colores y estampados | Relativamente barato |

El uso de estos materiales mantiene los costos bajos y los precios justos. Usted tambiénAyudar al planetaAsí que tu marca se queda fuera. Siempre pregunte a su fabricante sobre ofertas a granel para estas telas. Comprar a granel reduce el costo de cada traje de baño.

Agilizar la producción

Puede ahorrar dinero haciendo que su proceso de producción sea simple. Aquí hay algunas maneras de hacer esto:

Hacer trajes de baño en casa para ahorrar tiempo y dinero.

Elija telas que sean de buena calidad pero no costosas.

Ordene sólo lo que necesita para evitar el stock adicional.

Si hace que la producción sea fluida, controla mejor los costos. Los pedidos más grandes repartan los costos sobre más trajes de baño. Esto hace que cada traje de baño sea más barato. Puede ofrecer a los clientes mejores precios y mantenerse a la vanguardia.

Nota: Un buen plan de producción ayuda a evitar errores y costos adicionales. Usted consigue trajes de baño más rápido y mantener sus precios claros.

Factor en costos adicionales

Cuando planifique su línea de trajes de baño, debe pensar en los costos adicionales que pueden sorprender. Estos costos pueden cambiar su presupuesto rápidamente. Si sabe qué esperar, puede evitar sorpresas y mantener su negocio fuerte.

Honorarios de muestreo

Las tarifas de muestreo pueden sumarse rápidamente. Usted paga estas tarifas cuando desea ver una muestra de su diseño antes de realizar un pedido a granel. La mayoría de los fabricantes cobran entre $50 y $300 por cada muestra, dependiendo de cuán complejo sea su diseño. Si desea muestras para una colección completa, puede gastar entre $200 y $600. Algunas compañías, como Tideline, cobran $99 por el desarrollo del diseño, y algunas veces obtienes la mitad de eso si haces un pedido grande. Las muestras diseñadas a medida generalmente cuestan el doble del precio al por mayor más una tarifa de desarrollo. Si va por una ruta premium, los costos totales de muestreo pueden alcanzar los $2.000.

Cada muestra: $50-$300

Muestras de la colección: $200-$600

Tarifa de diseño personalizado: $99 por diseño

Desarrollo de la muestra: $10-$1.000

Consejo: Pregúntele a su fabricante si acreditará parte de su tarifa de muestreo para su pedido a granel. Esto puede ayudarte a ahorrar dinero.

Revisiones

Es posible que tenga que hacer cambios en sus muestras. Las revisiones pueden costar más, especialmente si desea cambiar las telas, los colores o el ajuste. Algunos fabricantes incluyen una ronda de revisiones de forma gratuita, pero la mayoría cobran por cambios adicionales. Si desea evitar los altos costos de revisión, comparta instrucciones claras y paquetes técnicos desde el principio. Esto ayuda al fabricante a obtener su diseño correcto la primera vez.

Primera revisión: a menudo gratis

Revisiones adicionales: $20-$100 cada una

Cambios importantes: puede costar más

Nota: La comunicación clara le ahorra dinero y tiempo. Siempre revise su diseño antes de enviarlo al fabricante.

Extras de envío

Los gastos de envío te pueden sorprender. Usted paga por el envío de muestras y pedidos a granel. Los envíos de la muestra toman generalmente 4-7 días laborales y cuestan $50-$150 por el envío. Los envíos a granel también toman 4-7 días, pero necesita agregar tiempo de aduanas. El envío a América del Norte cuesta alrededor de $1,10 por unidad, Europa es de $1,20 y Australia es de $0,90. Las aduanas y los aranceles pueden agregar más cargos, así que prepárese para ellos.

Tipo de envío | Tiempo de plomo | Coste (por unidad) |

|---|---|---|

Envíos de muestra | 4-7 días laborales en todo el mundo | $50-$150 por envío |

Envíos a granel | 4-7 días + aduanas | NA: $1,10, UE: $1,20, AU: $0,90 |

Aduanas & Deberes | Varía | Pueden aplicarse cargos adicionales |

Consejo: reserve fondos adicionales paraHonorarios de documentos, desarrollo de etiquetas personalizadasY los impuestos de importación. Estos costos pueden cambiar con cada envío, por lo que siempre verifique antes de realizar el pedido.

El tiempo y las estrategias estacionales

Órdenes fuera de temporada

Puede ahorrar mucho dinero al realizar sus pedidos de trajes de baño durante la temporada baja. Cuando termina el verano, muchos proveedores quieren limpiar su inventario. A menudo ofrecen grandes descuentos en materiales y productos terminados. Si compra trajes de baño o telas en elFinal del verano o durante las ventas de liquidación, Obtienes precios más bajos. También evita la prisa cuando todos los demás están tratando de ordenar para la próxima temporada.

Compre las ventas de fin de temporada para obtener grandes descuentos.

Compre por adelantado para bloquear los precios fuera de temporada.

Evite pagar el precio completo durante la demanda máxima.

Consejo: Planifique sus pedidos para los meses en que la demanda caiga. Encontrarás mejores ofertas y tendrás más opciones.

Planificación anticipada

La planificación anticipada le da más control sobre su presupuesto y producción. Cuando comienzas temprano, puedes usar herramientas de diseño de código abierto y software de inventario. Estas herramientas te ayudanReducir los costos y mantener su calidad alta. También puede negociar compras de telas a granel, lo que reduce los costos de materiales. Las estrategias de inventario justo a tiempo lo ayudan a evitar existencias adicionales y dinero desperdiciado.

Utilice herramientas de diseño para ahorrar en desarrollo.

Comprar tela a granel para mejores precios.

Utilice el software de inventario para rastrear sus existencias.

Ordene sólo lo que necesita para evitar desperdicios.

Nota: La planificación anticipada le ayuda a mantenerse organizado y a mantener bajos los costos.

Evite las tarifas de Rush

Las tarifas de Rush pueden comerse sus ganancias rápidamente. Puede evitar estos cargos adicionales haciendo sus pedidos temprano. Los fabricantes a menudo cobran más por solicitudes de última hora o pedidos pequeños. Si planifica con anticipación, obtendrá mejores precios y más tiempo para verificar la calidad. Trate de negociar cantidades mínimas de pedido que se ajusten a sus necesidades. También puede comenzar con una orden de prueba para probar el fabricante antes de hacer un gran compromiso.

Haga los pedidos temprano para omitir las tarifas de prisa.

Comience con una pequeña orden para verificar la calidad.

Elija diseños simples y tejidos de gama media paraMantener los costos bajos.

Consejo: La planificación temprana significa que nunca tendrá que pagar más por trabajos apresurados. Usted obtiene los mejores precios y mantiene su negocio funcionando sin problemas.

Usted puede obtener un gran valor para su línea de trajes de baño por ser inteligente. Comience conAsociaciones ODMPara ahorrar dinero y trabajar más rápido. Siempre busque en el mercado antes de elegir un fabricante. Compruebe su reputación, control de calidad y certificaciones. Cuando pides citas,Mirar las muestras de cerca. Compruebe la tela, costura y ajuste. Hable sobre los horarios de pago y la flexibilidad de MOQ cuando negocie. Asegúrese de hablar con claridad y mantener todas las ofertas fáciles de entender. Estos pasos lo ayudan a construir asociaciones sólidas y proteger su dinero. Te mantendrás por delante en el mercado de trajes de baño.

Pasos siguientes:

Haga una lista de verificación para su línea de trajes de baño.

Póngase en contacto con los fabricantes para obtener cotizaciones.

Mire las muestras y hable sobre términos importantes.

Consejo: Una investigación cuidadosa y ofertas claras ayudan a su línea de trajes de baño se destacan y le dan un valor real.

Preguntas frecuentes

¿Cuáles son los principales componentes de costo en la fabricación de trajes de baño?

Usted paga por los materiales, mano de obra, embalaje, envío y controles de calidad. Cada parte se suma a sus costos. Usted necesita ver estos componentes de costos en la fabricación de trajes de baño para que pueda ahorrar dinero y planificar su presupuesto.

¿Cómo afecta la calidad y el tipo de tela a los costos?

La calidad y el tipo de la tela cambian mucho sus costos. Si eliges telas premium o ecológicas, pagas más. Las telas más baratas reducen los costos, pero es posible que no duren tanto. Siempre pregunte a su fabricante sobre las opciones.

¿Por qué los costos cambian con el tamaño de la orden?

Cuando pides más trajes de baño, tus costos por pieza bajan. Los fabricantes dan descuentos a granel. Si ordena menos, los costos suben. Necesita equilibrar el tamaño de su pedido con su presupuesto y la demanda del consumidor.

¿Cómo puedo controlar los costos al lanzar una nueva línea de trajes de baño?

Debe comparar cotizaciones, elegir diseños simples y planificar su inventario. Observe sus costos en cada paso. Pregunte acerca de ofertas a granel y condiciones de pago. Si mantiene las cosas simples, puede administrar los costos y hacer crecer su marca.